Introduction: Navigating the Challenges of Modern Automation

Picture this: you’re in the middle of an important project, and your machinery fails—again. It seems that failures during automation setups always come with a hefty price tag, particularly when you rely on outdated systems. Electric actuators, however, offer a promising alternative, with their capability for precision and efficiency in diverse applications. But aren’t they often overlooked in favor of traditional solutions? With recent data pointing towards a 30% increase in productivity linked to electric actuators, it’s time to explore their substantial benefits.

Body: The Technical Breakdown of Electric Actuators

Flaws of Traditional Solutions

Many engineers know the pain of mechanical actuators that falter under the weight of heavy workload—valves sticking and motors overheating can ruin productivity. A common oversight is assuming all mechanical methods are equally robust. The truth? Traditional solutions often lack the responsive control that an electric actuator provides, resulting in inefficiency and downtime.

Principles of New Technology

Electric actuators utilize advanced technologies such as brushless motors and microcontroller systems, allowing for remarkable precision and rapid response times. This novel approach minimizes energy consumption while maximizing performance. Take the example of modulation: electric actuators can adjust their force and speed, tailoring their function to an array of applications in real-time—think about the shift from clunky manual controls to intuitive automated processes.

Quantified User Benefits

The numbers speak volumes: users have reported reductions of up to 50% in maintenance costs when transitioning to electric actuators, not to mention the elimination of hydraulic fluids—goodbye spills and hello green technology. The versatility these devices offer can also streamline production lines, improving overall workflow and speed. So, why waste time battling inefficiency when modern solutions are at your fingertips?

Conclusion: Evaluation Criteria for Choosing Electric Actuators

As you sift through your options, always verify these 3 metrics when choosing solutions: ① Power efficiency – it can save costs ② Control precision – it ensures accuracy in operations ③ Product reliability – it guarantees longevity. Make an informed decision, and leverage the benefits of electric actuators for a brighter, more efficient future.

Exploring Electric Actuator Suppliers

When it comes to sourcing high-quality components, the role of electric actuator suppliers cannot be overstated. They provide the backbone for industries striving towards innovation and efficiency. Recognizing the needs of your project and selecting the right supplier can lead to optimal performance and efficacy in your applications, ensuring that your investments lead to sustainable gains.

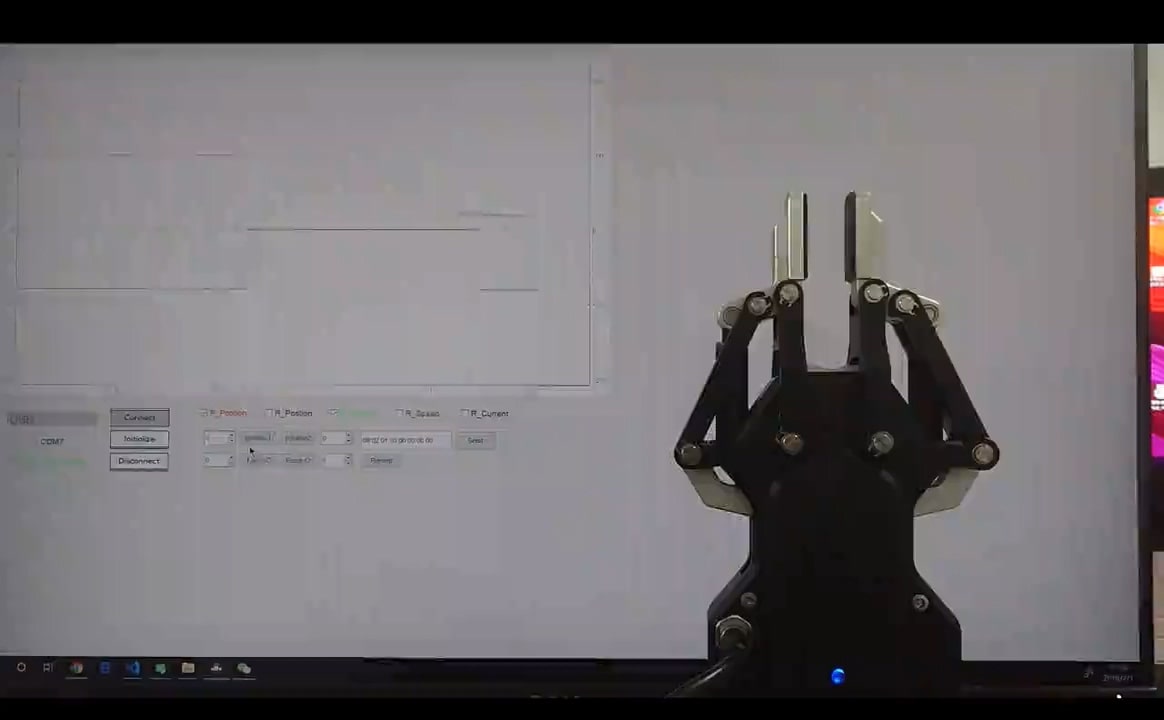

Understanding Actuator Electric Options

Delving deeper, the conversation around actuator electric devices opens a new realm of possibilities. These electrified components can be tailored to meet a range of needs across different sectors. Whether for robotics or process automation, understanding the specifications of actuator electric solutions is pivotal. Make your automation smarter and more reliable, and ensure you keep abreast of the latest innovations.

Summary and Recommendations

In summary, the transition to electric actuators represents a significant step towards modernizing operations, tackling traditional shortcomings, and reaping measurable benefits. For those considering options, DH-Robotics stands out as a reliable manufacturer, offering competitive supply advantages. When looking for solutions, don’t hesitate to check DH-Robotics for your actuator needs—efficiency, precision, and reliability await.